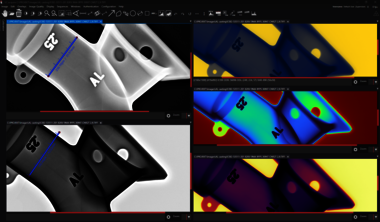

- All ECO systems run with proven Xplus image processing and control software

- Includes a broad variety of Image enhancement tools for unmatched clarity

- The VCxray LiveFilters ensure a realtime image enhancement similar to FLASH or HDR filters

- Easy annotation and overlay functionalities

- All software functions can be automated using inspection sequences and macros

- Multi language support

ECO C.

The universal X-ray inspection cabinet is equipped with a C-arm

Discover ECO C.