X Line

Maximum flexibility

VCxray has the talent and experience to help you create whatever solution is required – the key is to determine the right amount of technology and automation that fits your process, budget, and inspection requirements. On one extreme, this could be a system handling massive parts and weighing several tons. On the other end, this could be a high-speed in-line system processing hundreds of parts per hour.

Choosing advanced technology may not always make sense, but when it does the return on investment can be remarkable. Due to the modular approach we take with all of our solutions, the use of our x.OS software is the core for ALL solutions, and with our deep experience providing these solutions, we pride ourselves on our ability to work directly with you to meet goals, reduce risk, and succeed together.

Contact us with YOUR challenge!

It all starts with the needs and requirements of our customers in mind. What is the problem to solve? What is the goal to accomplish? Using our deep understanding and considerable experience, our solution architects and engineers team up to create the ideal solution together with our customers.

Wether it is a modification of one of our standard products, or the creation of a complex project from scratch, our team always has your inspection challenge in mind. We use application studies as well as mechanical and x-ray simulation to not only help visualize the solution, but to also reduce risk by proving feasibility.

It is this capability to envision, create, design, and validate a solution with you in the earliest stages possible that guarantees joint success.

VCxray’s engineers use sophisticated tools and software to help create the exact solution that is needed. We build everything first in the digital space, and use our mechanical, automation, and x-ray simulation tools to ensure project feasibility. This also gives the advantage of confirming the proper imaging chain, geometry etc.

Creating something virtually is a great start, but it doesn’t solve the problem by itself! That is where the team steps in and takes the previously envisioned solution and finalizes the design.

Using an extension of the same professional tools used to create the solution concept, our team executes the process required to make the concept a reality – then the production process begins that makes the dream com alive.

Many of our systems rely on unique solutions because our customers have unique parts and processes. Their inspection needs are not just about the final image, the system itself needs to fit into the daily work and production procedures as well. A large part of our consultation process includes understanding the „big picture“.

Only by this, we can ensure highest efficience and quality, compared to off the shelf systems.

This adaptability to different processes often requires us to think about a range of possibilities. In some cases, a more simple, manual approach may be sufficient, and in others, a complex inspection solution is required. Together, we can create everything from manual/standalone inspection stations to offline cabinet approaches, to at-line inspection machines, to in-line solutions – applying the appropriate level of automation.

Often times our standard products are sufficient to fulfill the requirements, but there are some cases where just a little bit „more“ is needed.

VCxray is unique in the sense that we can easily add that something extra that is needed. Some examples of this would be unique lading concepts for standard cabinets, customized part holders, new x-ray tubes and detectors, and even the extension of inspection envelopes and cabinet sizes – we can do whatever it takes.

When our standard cabinets are not perfectly suited for the inspection task, and even modifications of them are not practicable, then we can bring out our most advanced tools. We reach into our experience of hundreds of solutions to find the combination of technologies that solves our customer’s tasks on their terms.

Robots, cobots, gantrys, and custom manipulators that fit your exact process are all tools that we are very familiar with.

Sometimes the casics work just fine, but additional automation can significantly boost efficiency and performance. VCxray can integrate fim, CR, and even other modylities with our solutions in order to help gain every bit of functionality possible.

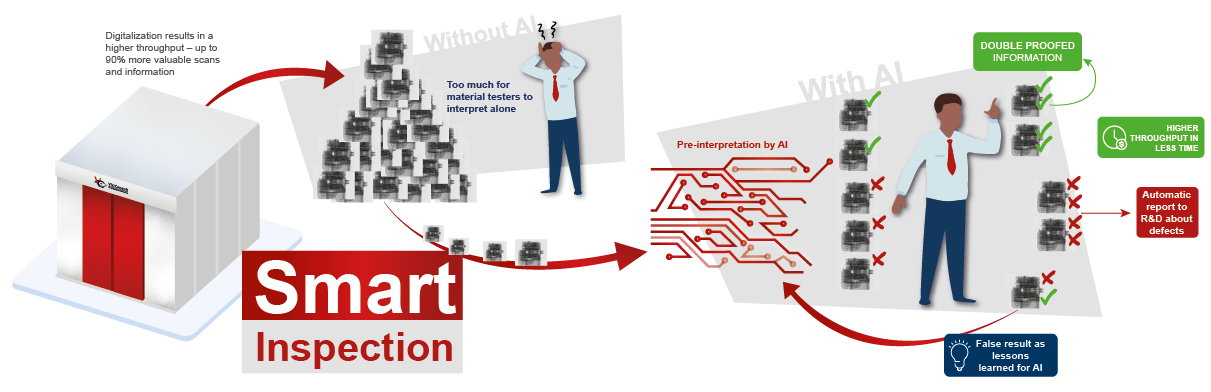

Getting your images into the digital world enables significant gains - mainly as a result of the new automation opportunities. VCxray has integrated a wide variety of imaging chain combinations, and work with our customers to find the perfect combination to start them on the path to digital transformation.

CT adds yet another dimension of image information about our customer's parts and processes. Once thought of only as expensive and slow, modern CT applications are more affordable and can surprisingly be extremely fast! Depending on the ultimate needs, a CT solution may be exactly what is needed.

The x.OS is an innovative software ecosystem that is both comprehensive and configurable at the same time. This modular approach can be used as separate offline applications or can be configured as an interconnected online solution - and virtually everything in between.

Make your company fit for the future and digitize your X-ray processes now.

Whether or not the final disposition is made manually, decided using computer assistance to help make the call, or even with totally automatic ADR/AI decisions, VCxray can accommodate them all. No matter where on the scale you are regarding decision automation, we can design our system around your needs. We can help you determine what level is right for your application while giving you a "future-proof" path forward.

Contact our experts to talk about your projects and challenges

With our Service centers and Hubs worldwide,

we will complete your staff with maximum

efficiency in your specified time frame and

without interrupting your operations.

No matter where you are, we are never far away.

Our knowledge and experience

maximize your company‘s profits.